Design & Developed by Themeseye

When a client needs CNC services, they often wonder how quickly they can get the parts back. Today’s technology allows digital manufacturers to create pieces more efficiently, offering a fast turnaround time to save customers money. With digital aluminum CNC machining processes, it’s easier than ever to get your part made affordably.

Manufacturers who use the newest technology differ vastly from those who use traditional methods. Shops using older methods require manually operated machines, which creates more work and reduces productivity. On the other hand, many shops that are providing digital CNC machining services have automated machines.

Modern technology allows machining companies to offer quick turnaround times. That is partly because their processes do not require as much labor, allowing them to produce more parts. The result for the customer is that the pieces get delivered on time and fit their budget.

Today’s CNC shops are always looking for ways of simplifying things to save their customers money. For example, Promark Tool and Manufacturing has updated its modeling software to Solid Works 2020 for its CAD drawing and MasterCam 2020 for its CNC machines. Implementing these changes is often behind-the-scenes work, but it can increase productivity and allow a shop to create more consistent results.

There are a few things to look for when picking a shop. For example, you should ask about the part volumes they specialize in. Some shops can produce thousands of parts at a time, and others offer lower volumes.

In addition, they should offer several manufacturing options. For instance, you may want a specific prototype method, but another approach might be more affordable. That way, you can choose from a couple of options and save money in the process.

Feel free to ask the shop questions about how the process works. It’s best to pick a shop that uses automation to reduce setup costs. See if it offers prototyping services, so you can fix any manufacturing problems before beginning production. That saves money since you will not need to rework the product mid-production.

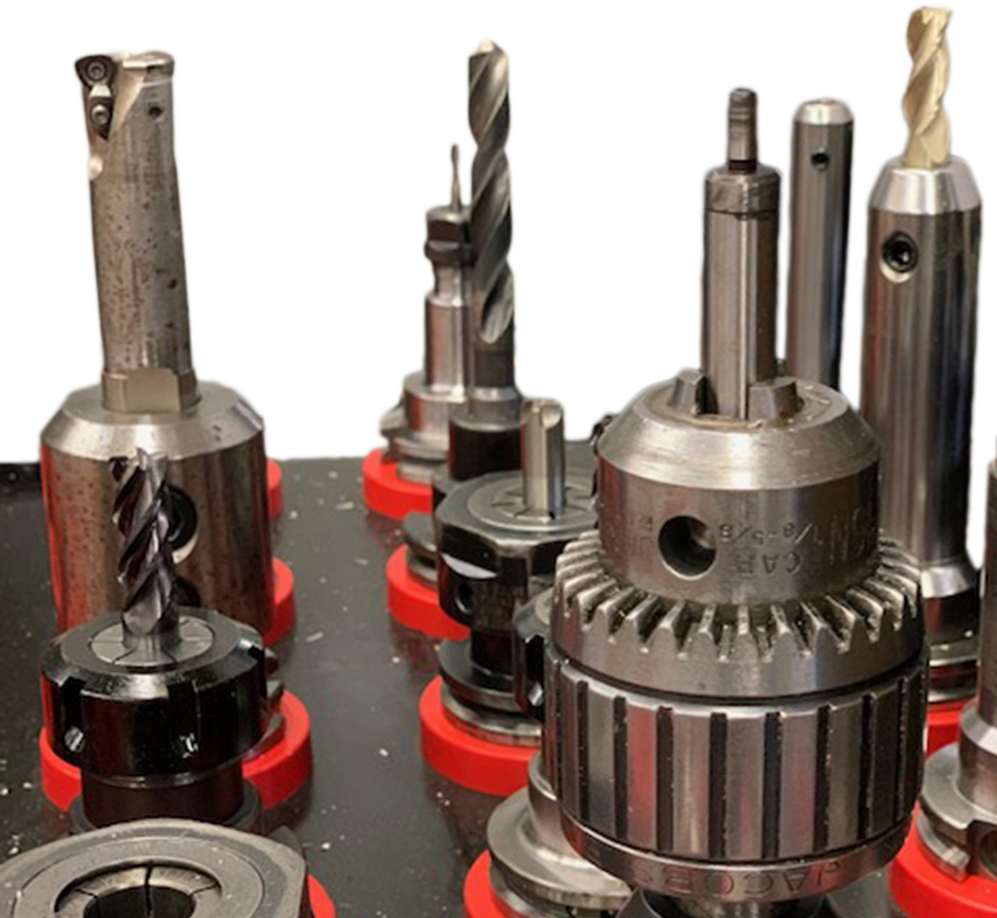

Finally, learn about the toolsets used since some allow for faster turnaround speeds. Some shops have a fixed number of tools, meaning they might have to do double-duty.

Working with a digital machining company comes with many advantages. For example, it lets the part go from design to final piece quickly. Automation also allows for faster production and affordable, multiple iterations of a creation. Plus, it lets you send products to market faster. If you want to know more about the advantages of automation in custom CNC machining, contact Promark Tool and Manufacturing today.