Some of Our Clients

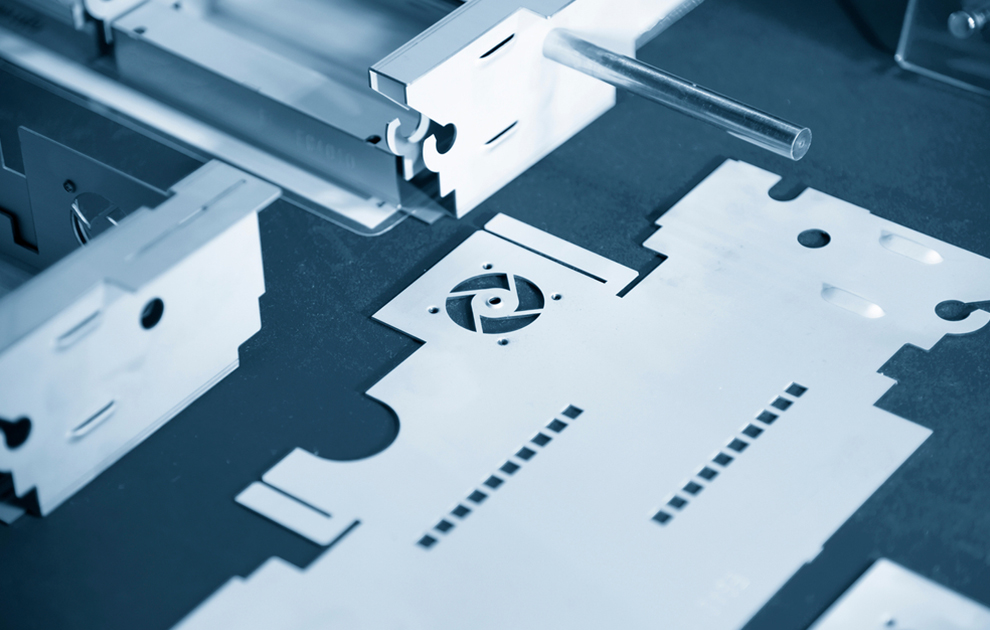

Precision custom metal stamping is a process that involves the use of specialized tools and machinery to create intricate and detailed parts for a variety of industries. One industry that greatly benefits from precision custom metal stamping is the lighting industry.

In the lighting industry, precision custom metal stamping is used to create a wide range of parts and components, including reflectors, heat sinks, and mounting brackets. The precision and accuracy of the stamping process ensures that these parts fit perfectly and function as intended, providing optimal performance and longevity for the lighting fixtures.

One of the key benefits of precision custom metal stamping for the lighting industry is the ability to produce parts with complex shapes and designs. This allows for the creation of unique and innovative lighting fixtures that stand out in the market. Additionally, precision custom metal stamping allows to produce parts in large quantities at a relatively low cost, making it an economical option for manufacturers.

To ensure precision and accuracy in the custom metal stamping process, it is important to work with a reputable and experienced manufacturer. This will ensure that the parts produced meet the necessary specifications and tolerances, and that the process is carried out in a safe and efficient manner. Additionally, it is important to use high-quality materials and tooling in the stamping process to ensure the longevity and durability of the parts produced.

Overall, precision custom metal stamping is a vital process in the lighting industry, allowing to produce complex and high-quality parts that are essential for the function and performance of lighting fixtures. By working with a reputable and experienced manufacturer and using high-quality materials and tools, manufacturers can ensure that the custom metal stamping process is carried out with precision and accuracy.