Some of Our Clients

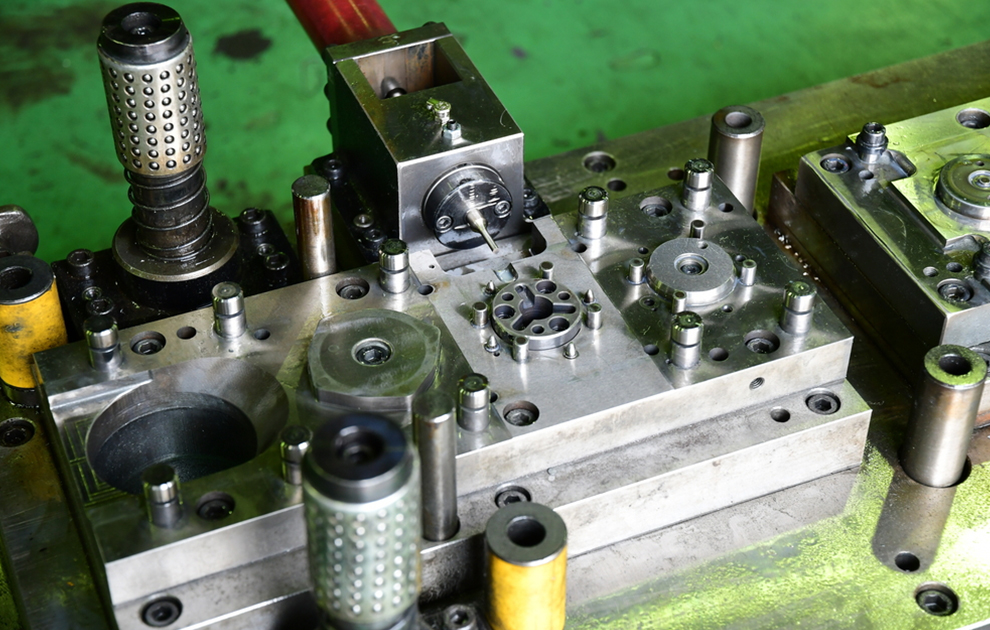

Precision custom metal stamping is a process that is widely used in the military industry to create a wide range of components and parts. It is a cost-effective and efficient way to produce high-quality parts that meet the specific needs of the military. Here are some pointers on precision custom metal stamping for the military industry:

In conclusion, precision custom metal stamping for Military is a cost-effective and efficient way to produce high-quality parts for the military industry.

By selecting the right material, designing the right tooling, implementing strict quality control, and having a reliable lead time, manufacturers can ensure that they meet the specific needs of the military industry.