Ways to Turn Your Idea Into a Product Prototype

Product prototyping is an essential step in the product development process. It lets potential customers give input on the design, function, and overall user experience. Prototyping also allows design improvements before mass production, saving time and money.

A reliable provider of prototyping services offers various ways to develop the product idea. Each method has its advantages and disadvantages. The best method will depend on the product type for development, budget, and timeline constraints.

Why Product Prototyping is Important

Creating a prototype is essential in many businesses for the following reasons:

- Before companies can bring a product to market, it must exist in some form. That form is the prototype. Prototypes are essential for testing products before they become available to consumers.

- Prototypes help assess feasibility and usability. They also help identify potential problems early on, saving time and money in the long run.

- They also communicate the product idea to other people who may be involved in its development or eventual manufacture.

- A well-designed prototype can help avoid problems that could otherwise only be discovered once the product is already in production.

Common Methods of Prototyping

The most common prototyping methods a product prototype company will use include:

- Punch press

- Fabrication

- Welding

- Fastener insertion

- Metal clinching

Punch Press

A punch press is a machine press that uses a die to shear, blank, draw, or form metal. Punch presses can create complex shapes with a high degree of accuracy.

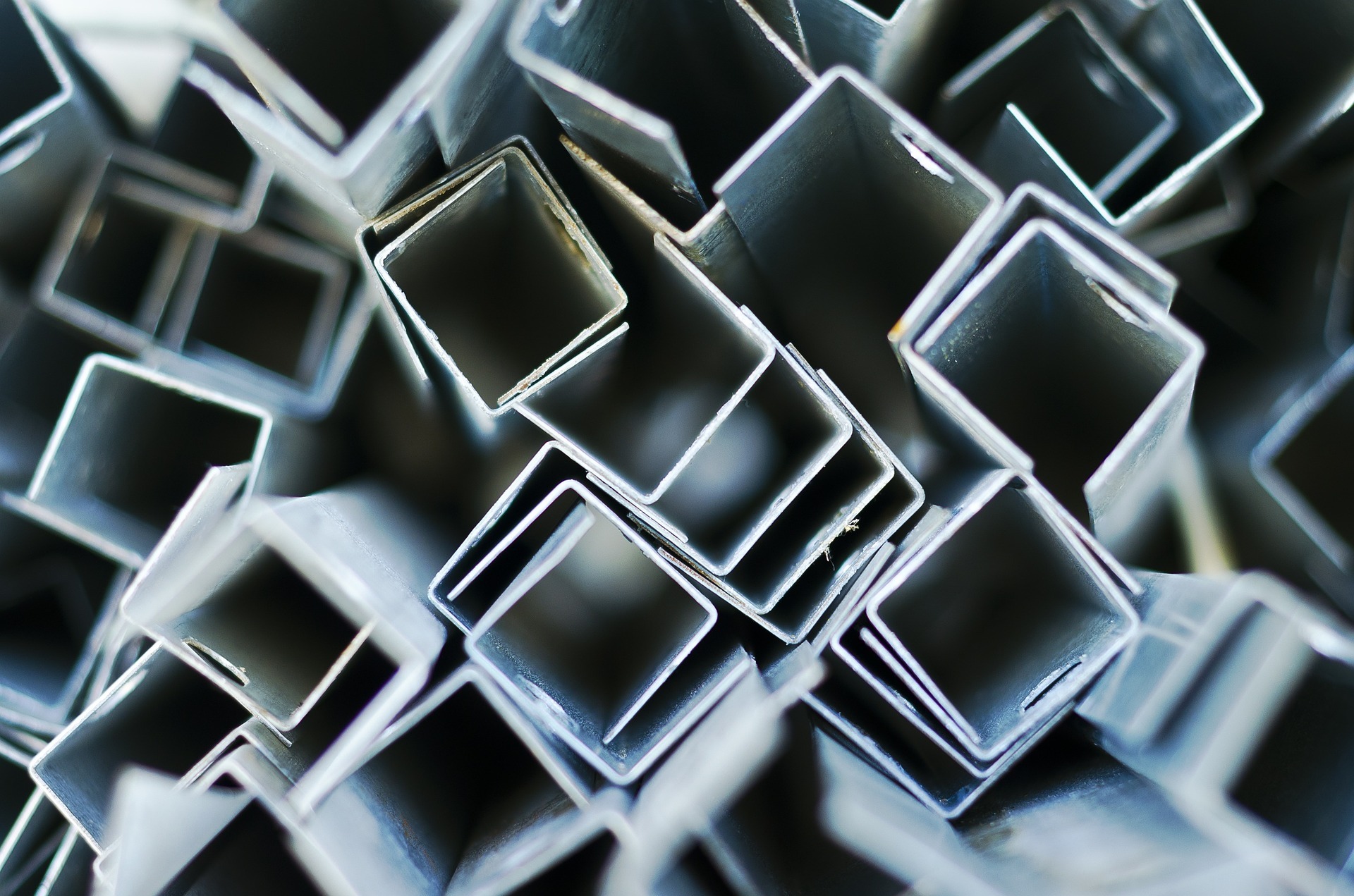

Fabrication

Fabrication involves using assorted tools and machines to create the prototype from scratch. Fabrication can use various materials, including metals, plastics, and composites.

Welding

Welding is another common method for fabricating prototypes. This process involves joining two or more pieces of metal together using heat and pressure.

Fastener Insertion

Fastener insertion is a prototyping technique that includes introducing small metal pieces into the prototype. These can consist of bolts and nuts.

Metal Clinching

Metal clinching is a method of joining two pieces of metal without heat or pressure. Clinching uses a special tool to form a tight connection to between the metal.

Which Prototyping Method Is Right for the Project?

Creating a prototype will help validate your concept and get feedback from potential users. It’s an essential step in the product development process and should not be skipped. But, with so many different methods available, it can be hard to know which one is right for your project.

If unsure which method is suitable, it’s best to consult a prototyping services company. Promark Tool & Manufacturing Inc. is a provider of top-quality custom prototypes with over 40 years of experience. For more information, contact us today.