Design & Developed by Themeseye

In the fast-paced world of product development, prototypes are essential for helping manufacturers assess the feasibility of products and gather feedback. Prototypes allow companies to explore different designs options before

Read Full

Constructing metal structures requires customizing metal parts, which is called metal fabrication. Many products use metal fabrication, including automobile chassis, building panels, roofing, airplane fuselage panels, and more. The most

Read Full

Product prototyping is an essential step in the product development process. It lets potential customers give input on the design, function, and overall user experience. Prototyping also allows design improvements

Read Full

Sheet metal fabrication is a process that has three main steps: cutting, shaping, and assembly. To fabricate sheet metal parts, one will need various tools and equipment. Here are the

Read Full

Custom metal fabrication is the process of creating custom metal parts and components using various metals. The process involves cutting, bending, and welding metals to create the desired product. Custom

Read Full

When designers are ready to take their product from concept to reality, they turn to prototype companies. However, with so many options out there, it can be tough to know

Read Full

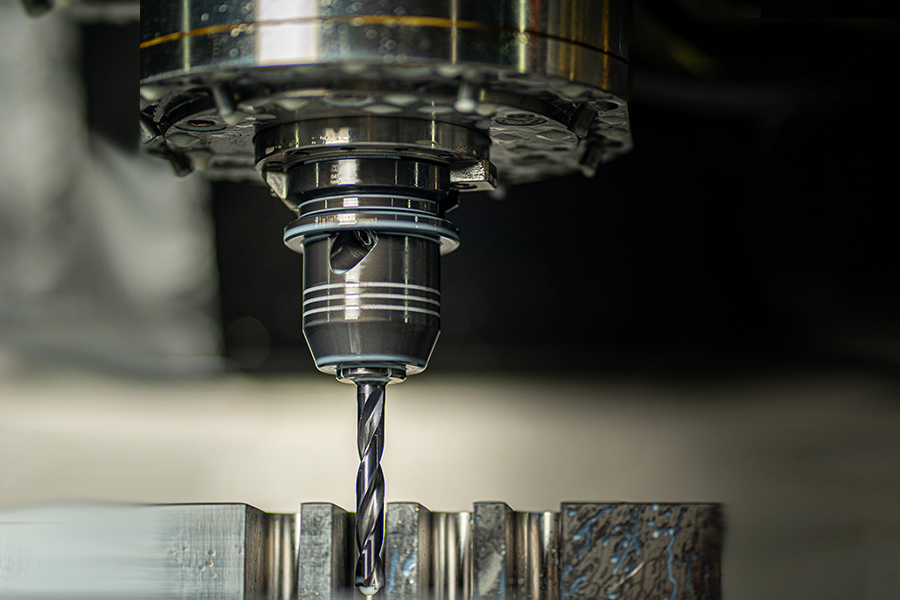

Businesses of all sizes benefit from the use of custom machined parts. Custom machining is not just for large companies. Small businesses in the GTA often reap the most benefits

Read Full

Sheet metal design is vital for creating a quality custom metal product. A designer needs to consider specific metal characteristics to ensure the product is affordable and feasible for custom

Read Full

When unfamiliar with 3-axis CNC machining, it’s natural to have some questions about how it works. Here are some of the most asked questions about 3-axis CNC metal machining and

Read Full

Metal stamping is a process in which machines are used to stamp out various shapes and sizes out of metal. It is most frequently used in the manufacturing industry to

Read Full