Design & Developed by Themeseye

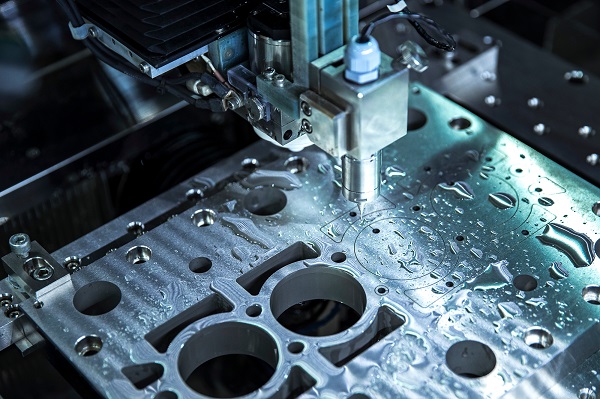

For all kinds of businesses associated with different industries and for a host of applications, demand for quality metal fabrication is at an all-time high. Sources that provide this type of service offer various processes. One of these is CNC machining, though it is one of the oldest techniques, it has now become incredibly advanced. This is why a lot of customers rely on this process for custom metal work.

When it comes to custom manufacturing, top companies still use CNC machining. Thanks to technological advances, it accomplishes numerous tasks. Some examples of these include drilling, bending, cutting, and forming. As a versatile and reliable technique, it remains a popular method for working with metal.

For the past several years, demand for Custom CNC machining has increased. The reason is that fabrication using this particular technique can meet all of the requirements. Even if that involves bumping up the number of layers, mounting multiple components, and completing complex designs.

Organizations that manually set up printed circuit boards have to factor in several things. That includes the PCB’s design, components, and layers. Also, this task is repetitive since it involves making multiple chips, all with the same thickness, size, shape, and so on. The other issue is that doing all these takes a lot of time. However, custom manufacturing companies that use CNC machining make the process much easier.

Below are just some of the benefits that come from CNC machining.

1. As part of custom manufacturing, a source can store the CAD design file in a computer hooked up to the CNC machine. That makes it possible to digitize the entire process, thereby minimizing the need for 2D drawings.

2. Experts test a machine’s calibration to ensure it matches up with the PCB.

3. Modern-day CNC machines are both scalable and modular. That allows fabricators to add one or two axes to a three-axis machine.

4. CNC machines can accommodate several complex geometric designs.

5. Today’s CNC machines offer either partial or full automation, as well as multiple axes.

6. It allows for a fast turnaround and reduces waste, which helps lower production costs

For top-of-the-line CNC machining services, choose to work with us at Promark Tool and Manufacturing. Contact us today to learn more about our custom metal work capabilities. We have a team of experts ready to discuss specific project needs.