Design & Developed by Themeseye

The aerospace industry is choosing more advanced processes when it comes to manufacturing today. These technologies have names such as digital manufacturing, advanced manufacturing, or smart manufacturing. No matter the title, the goal is to use prototyping services to offer a great solution.

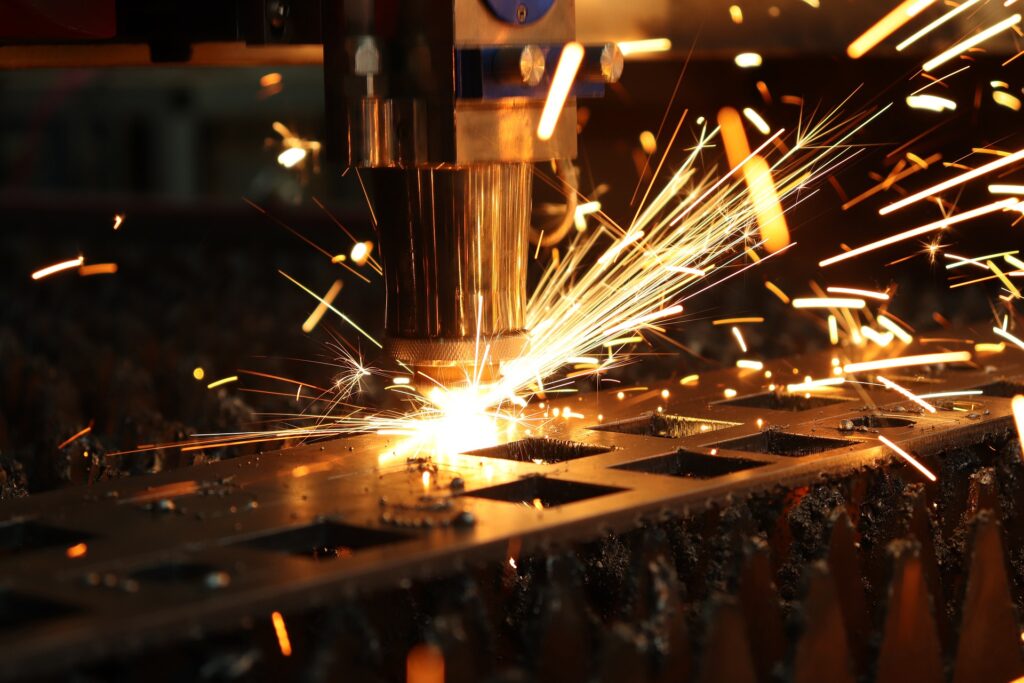

Companies might use metal additive manufacturing, which offers more possibilities when it comes to designing metal parts. Companies could combine it with CNC machining to provide a better finish on the surface. At the same time, it provides a tighter tolerance. Companies are choosing more production methods, meaning that additive manufacturing is a top choice.

The aerospace industry can easily benefit from additive manufacturing’s effectiveness when it comes to making it harder to create parts. There are several kinds of programs that require these mechanical parts. That has led to these companies looking for better sourcing, developing, and making the necessary products.

Today’s software is more advanced than ever since many companies have additive manufacturing in mind. Today’s CAD packages might be able to use one requirement set and then make many other products from it.

Since there are some newer manufacturing methods, companies will also need new designing processes. That means the company has to consider the production method at the beginning of a new concept. The company has to be able to use digital manufacturing to create that component. Still, it is also essential to optimise the design. That is where custom prototypes come in. Prototypes allow the company to determine if the design is the ideal method of creating the component.

When the company has decided on the best tool, the next job is to prototype the items. It might include creating a few iterations to test out, ensuring that the product is strong and has structural integrity. The company will also see if they can manufacture it easily. The company will want to try to speed up the manufacturing to increase the iteration time.

One of the advantages of additive manufacturing is that the company does not need to use moulds. It is possible to hasten the prototyping process, to help the product get to the market faster. It reduces the costs of labour, part development, and downtime that might result from a non-functioning component or part.

Are you looking for the right prototyping services for the aerospace job? If you are, you might consider turning to Promark Tool and Manufacturing The industry is choosing more powerful technologies to get things done. Contact us today to learn more.