Design & Developed by Themeseye

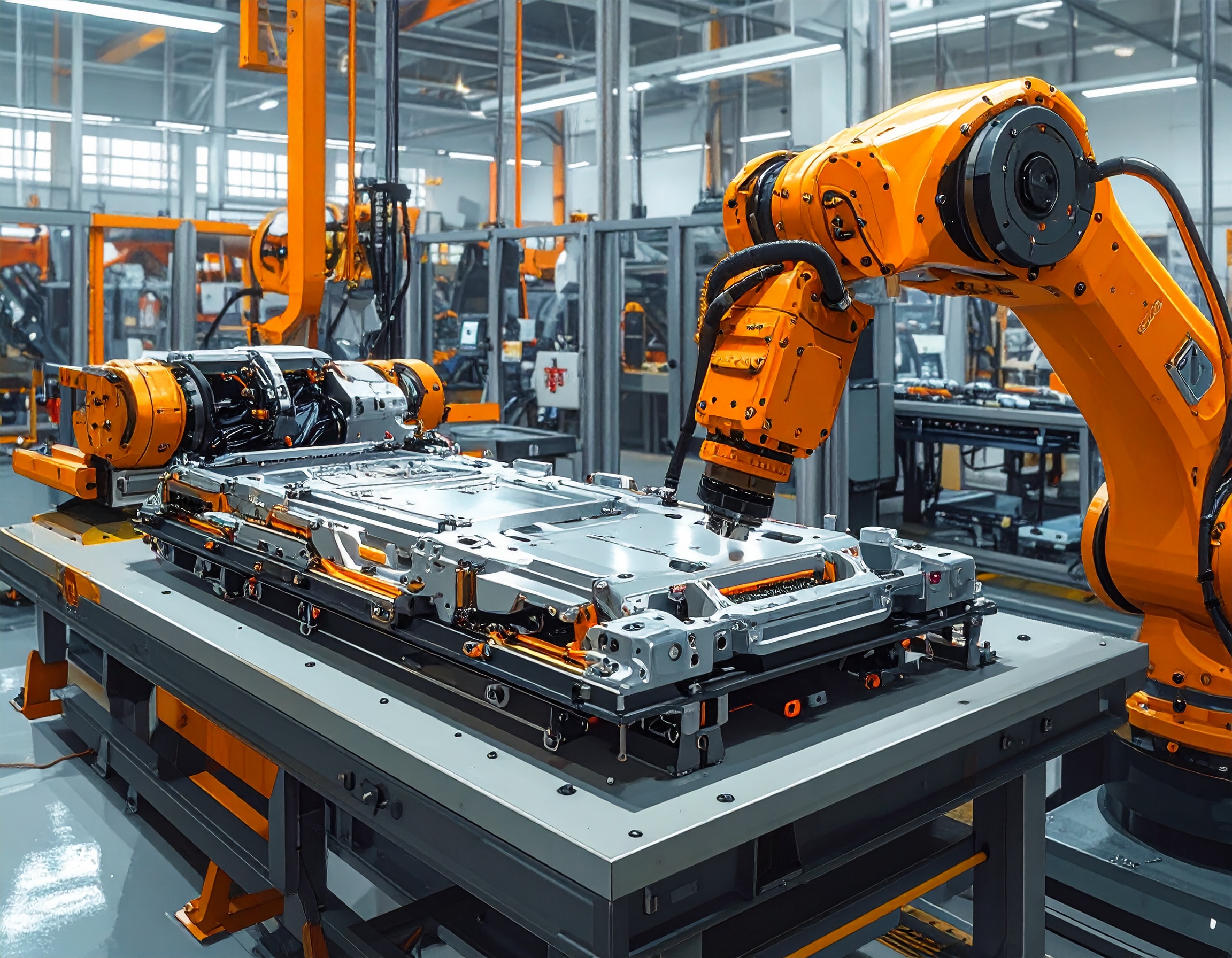

Mechanical assemblies are the backbone of numerous industries, including aerospace, automotive, electronics, and medical devices. Every assembly depends on precision, durability, and repeatability. Yet efficiency is often the deciding factor that determines whether a project succeeds in the real world.

This is where Design for Manufacturability (DFM) plays a vital role in mechanical assemblies. Integrating DFM principles early in the design process helps streamline production, reduce waste, and achieve consistent quality across every stage.

Design-for-Manufacturability is the practice of optimizing a product’s design to simplify the manufacturing process without sacrificing performance. The concept emphasizes collaboration between engineers and manufacturers during the design phase. This ensures cost-effective production of parts and assembly with minimal complications.

For electromechanical assemblies, DFM ensures:

The result is a design that translates smoothly from digital concept to physical product.

Mechanical assemblies often involve multiple components, each fabricated using processes like CNC machining, stamping, welding, or sheet metal fabrication. Without DFM, even minor design oversights can create costly problems.

Key benefits of DFM in mechanical assemblies include:

In aerospace and other regulated industries, where assemblies must meet standards such as AS9100D, DFM helps align designs with compliance requirements.

Also Read:

Unique Challenges with Mechanical Assemblies and Ways to Address Them

The Top Advanced Industries That Rely on Electromechanical Assemblies

Importance of Premium Quality and RoHS Compliance in Electromechanical Assembly

Integrating DFM in electromechanical assembly requires a systematic approach. Several principles guide successful implementation:

1. Material Selection Aligned with Process Capabilities

Choosing materials that are readily available and compatible with fabrication methods avoids costly substitutions or delays.

2. Standardization of Parts and Fasteners

Using standardized dimensions and fasteners reduces inventory complexity and simplifies assembly steps.

3. Minimized Tolerances

While tight tolerances may seem ideal, over-specifying them increases machining costs. DFM ensures tolerances are achievable without overburdening production.

4. Simplified Geometries

Designing parts with simpler shapes eliminates the need for multiple setups and specialized tooling.

5. Early Collaboration Between Teams

Engaging manufacturers during the design stage ensures that product concepts align with shop-floor realities.

These principles allow manufacturers to build assemblies that are both functional and efficient.

DFM principles complement Promark Tool and Manufacturing’s capabilities in progressive dies, CNC machining, and custom metal stamping. The company collaborates with clients to refine designs, ensuring manufacturability without compromising specifications.

From intricate parts to sealed enclosures, DFM principles guide the fabrication and assembly process to deliver precise and effective solutions. Certifications like ISO 9001:2015 and AS9100D highlight the ability to meet stringent industrial standards, often requiring rigorous DFM adherence.

Promark Tool and Manufacturing has embraced these principles since 1971. This has helped support industries in Canada and beyond with precision-driven assemblies backed by ISO 9001 and AS9100D.

Businesses seeking electromechanical assembly services in Toronto can partner with Promark Tool and Manufacturing. Backed by ISO 9001:2015 and AS9100D certifications, the team ensures manufacturability, efficiency, and compliance at every stage of the production process.