Design & Developed by Themeseye

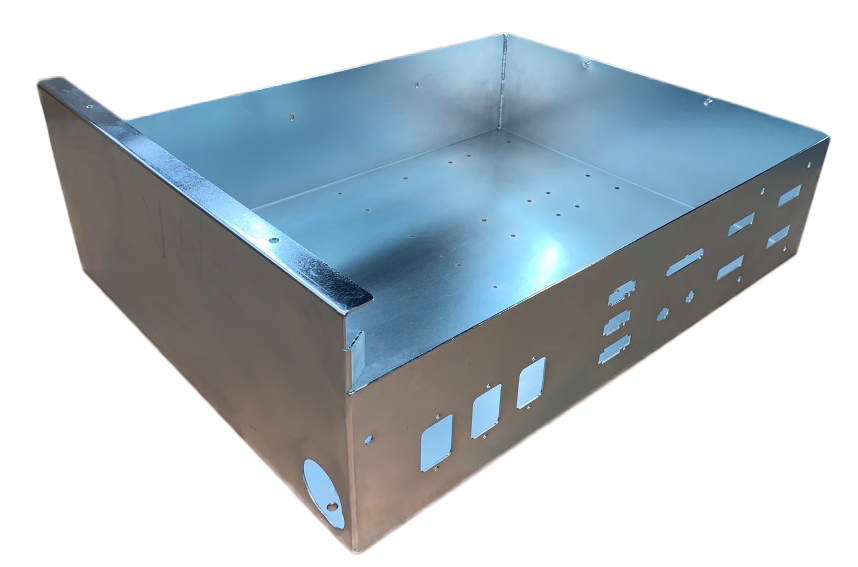

Quality Custom Metal Fabrication

Tailored to Your Specifications

Sheet metal fabrication signifies a sophisticated method crucial for producing a multitude of metal products. From designing intricate blueprints to the fabrication of various items, this process involves meticulous cutting, bending, and shaping thin sheets of metal into bespoke shapes and sizes.

Custom metal fabrication involves manipulating raw metal materials to create specific parts and structures. The final high-quality products bear testimony to the skilled technicians and specialized tools employed. From the aviation industry to construction and manufacturing, this method delivers bespoke solutions for a diverse range of applications.

The journey of custom metal fabrication begins with the design phase. Here, exact blueprints for the desired product are crafted. The subsequent material selection phase involves picking the right type and gauge of metal for the project. The metal undergoes numerous operations, including cutting, bending, welding, and finishing, to reach the desired form and size.

Whether it’s for a specific industrial requirement, a unique design project, or even an environmental initiative, custom metal fabrication serves various needs. When strength, durability, efficiency, customization, and recyclability matter, custom metal fabrication comes into play.

Similar to the sheet metal fabrication process, custom steel fabrication uses steel, a material known for its durability, strength, and resistance to corrosion. This process finds widespread applications in creating robust structures, high-performance equipment, and long-lasting machinery.

Custom sheet metal fabrication extends a wide range of benefits:

When selecting a sheet metal fabrication company, experience, expertise, equipment, and quality control are crucial. Promark Tool and Manufacturing, with its proven track record, fulfills these requirements, offering solutions that are not just cost-effective but also align with specific timelines.

With over 50 years in the industry, Promark Tool and Manufacturing’s extensive experience, state-of-the-art equipment, and commitment to delivering high-quality products make it a top choice. Add to this ability to handle complex designs, and the result is a provider ready to meet all custom sheet metal fabrication needs. Reach out to explore more about our capabilities or to request a quote today.

When it comes to custom sheet metal fabrication in Toronto, it’s essential to partner with a reliable and experienced manufacturer. Promark Tool and Manufacturing is a top choice for businesses that require high-quality custom sheet metal fabrication. Here are some reasons why:

Contact us today to learn more about our capabilities or to request a quote for custom sheet metal fabrication services.

Some of Our Clients

Custom sheet metal fabrication services are designed to meet the rigorous demands of each industry with precision and efficiency.

Sheet metal fabrication is used across numerous industries, including:

At Promark Tool and Manufacturing, our custom sheet metal fabrication services are designed to serve both prototyping and high-volume production needs for a variety of applications.

We work with a wide range of materials including stainless steel, aluminum, mild steel, galvanized steel, and more. Our custom sheet metal fabrication Toronto team ensures each project uses the right material for performance, durability, and appearance.

Absolutely. Whether you need a single prototype or high-volume production runs, our sheet metal fabrication capabilities are scalable. We support businesses of all sizes with flexible manufacturing solutions and competitive turnaround times.

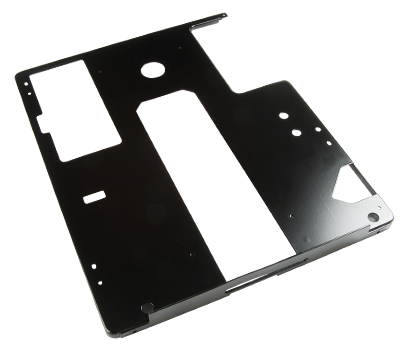

At Promark Tool and Manufacturing, our custom sheet metal fabrication services utilize advanced machinery for precision and efficiency. Our equipment includes CNC laser cutters, turret punches, press brakes, MIG and TIG welding stations, and automated assembly tools. This allows us to process a wide range of metals, including aluminum, stainless steel, and carbon steel, with high accuracy and repeatability.

Our standard turnaround time for custom sheet metal fabrication projects ranges from 5 to 15 business days, depending on complexity, volume, and material availability. For urgent jobs, we offer expedited services to meet tight deadlines without compromising quality.

We maintain strict quality control at every stage of the sheet metal fabrication process. This includes digital file verification, in-process inspections, CNC-controlled cutting for precision, and post-fabrication testing. Our experienced technicians and engineers follow ISO-compliant procedures to ensure every part meets your specifications and performance standards.

Sheet metal fabrication can be used to produce a wide variety of components and assemblies, including:

Promark’s custom sheet metal fabrication services are ideal for industries that require durable, precision-made metal parts.

Several machining methods are used in sheet metal fabrication, including:

These methods are often combined to meet the design and functional requirements of your metal components.