Some of Our Clients

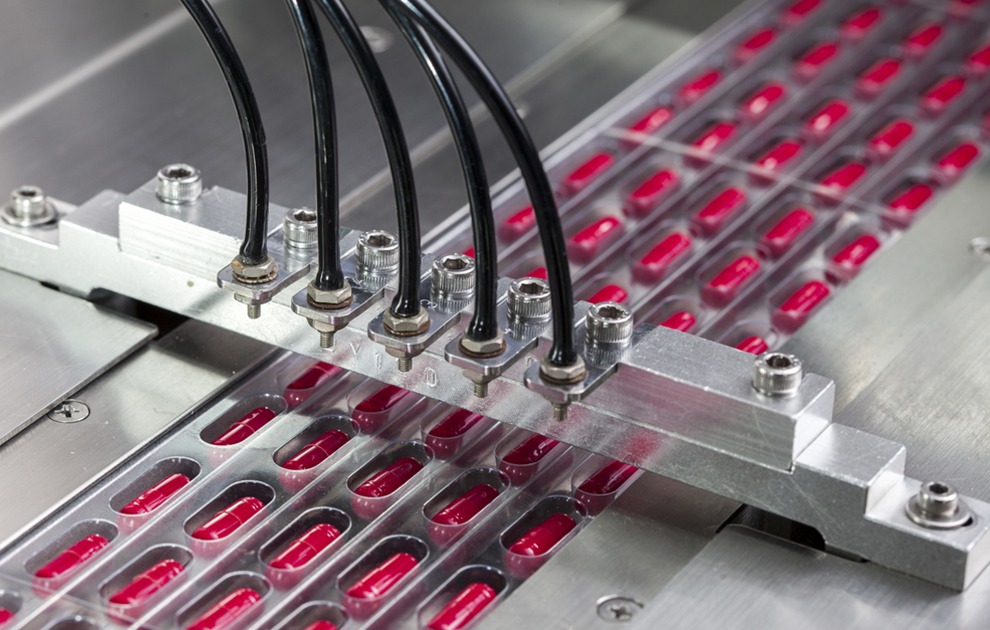

CNC machining is a process that involves the use of computerized numerical control to shape and form materials, such as metals and plastics, into precise and intricate parts and components. In the pharmaceutical industry, CNC machining is widely used to produce drug delivery devices, such as syringes and inhalers, as well as for the manufacture of medical implants and prosthetics.

One of the main benefits of CNC machining for pharmaceutical industry is the high level of accuracy and precision that it allows. With CNC machines, parts and components can be manufactured to extremely tight tolerances, ensuring that they meet the strict quality and safety standards required in the pharmaceutical industry.

Another advantage of CNC machining is the speed and efficiency of the process. CNC machines can produce parts and components much faster than traditional manufacturing methods, reducing lead times and increasing production capacity. In addition, CNC machining allows to produce complex geometries and shapes that may not be possible with other manufacturing methods.

To meet the stringent requirements of the pharmaceutical industry, CNC machining facilities must also adhere to strict cleanliness and contamination control standards. This includes the use of specialized equipment and materials, such as air filtration systems and sterile tooling, to prevent the contamination of products during the manufacturing process.

Overall, CNC machining services are an essential technology for the pharmaceutical industry, enabling the production of high-quality, precise, and reliable drug delivery devices and medical components that meet the needs of patients around the world.