Design & Developed by Themeseye

The finishing process often determines whether a metal component performs flawlessly or falls short of expectations in precision manufacturing. Metal stampings start as carefully formed pieces. However, the finishing stage

Read Full

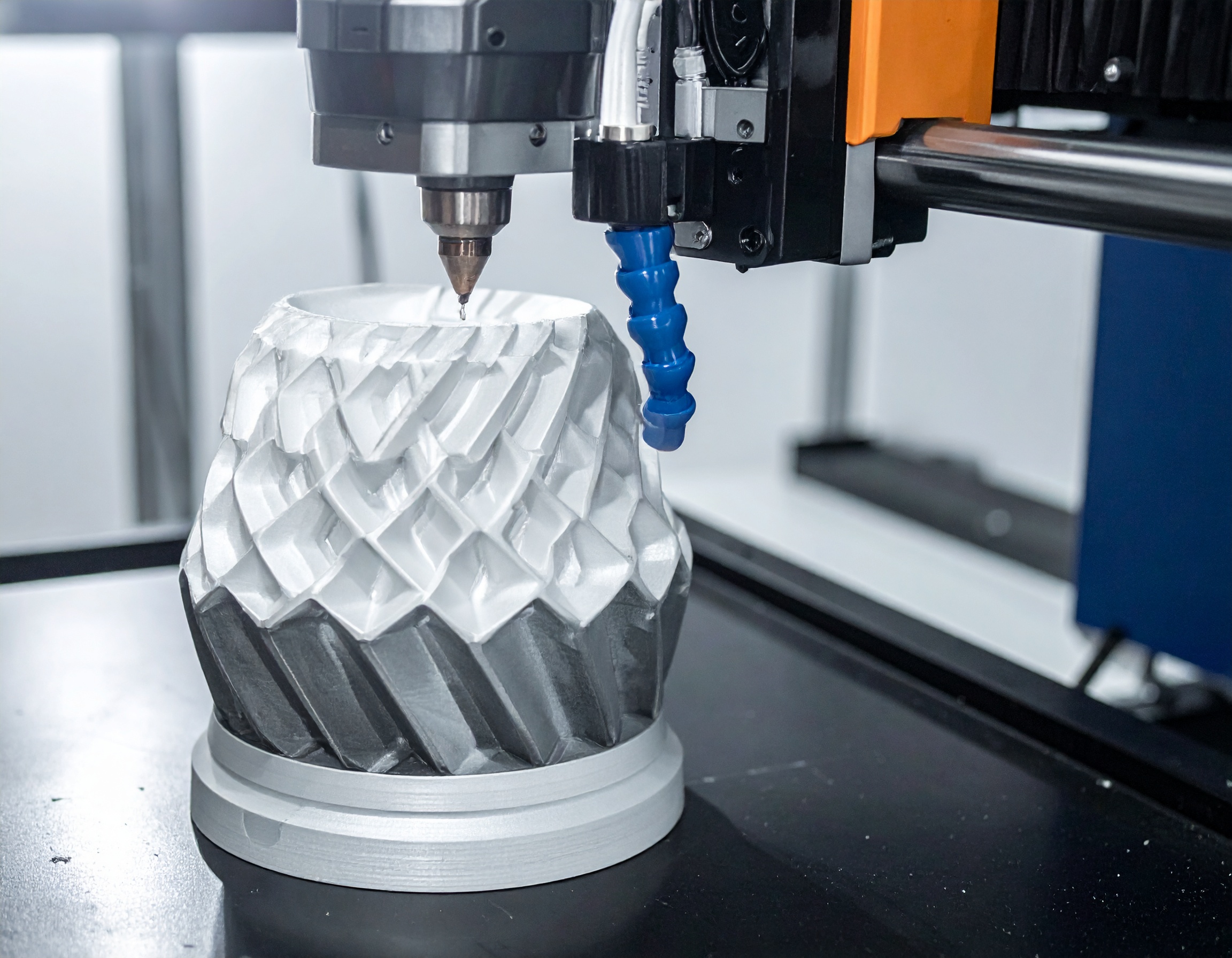

Efficient CNC machining begins long before metal reaches a mill or cutting tool. The earliest design decisions can influence lead times, material usage, machining accuracy, and overall project costs. Applying

Read Full

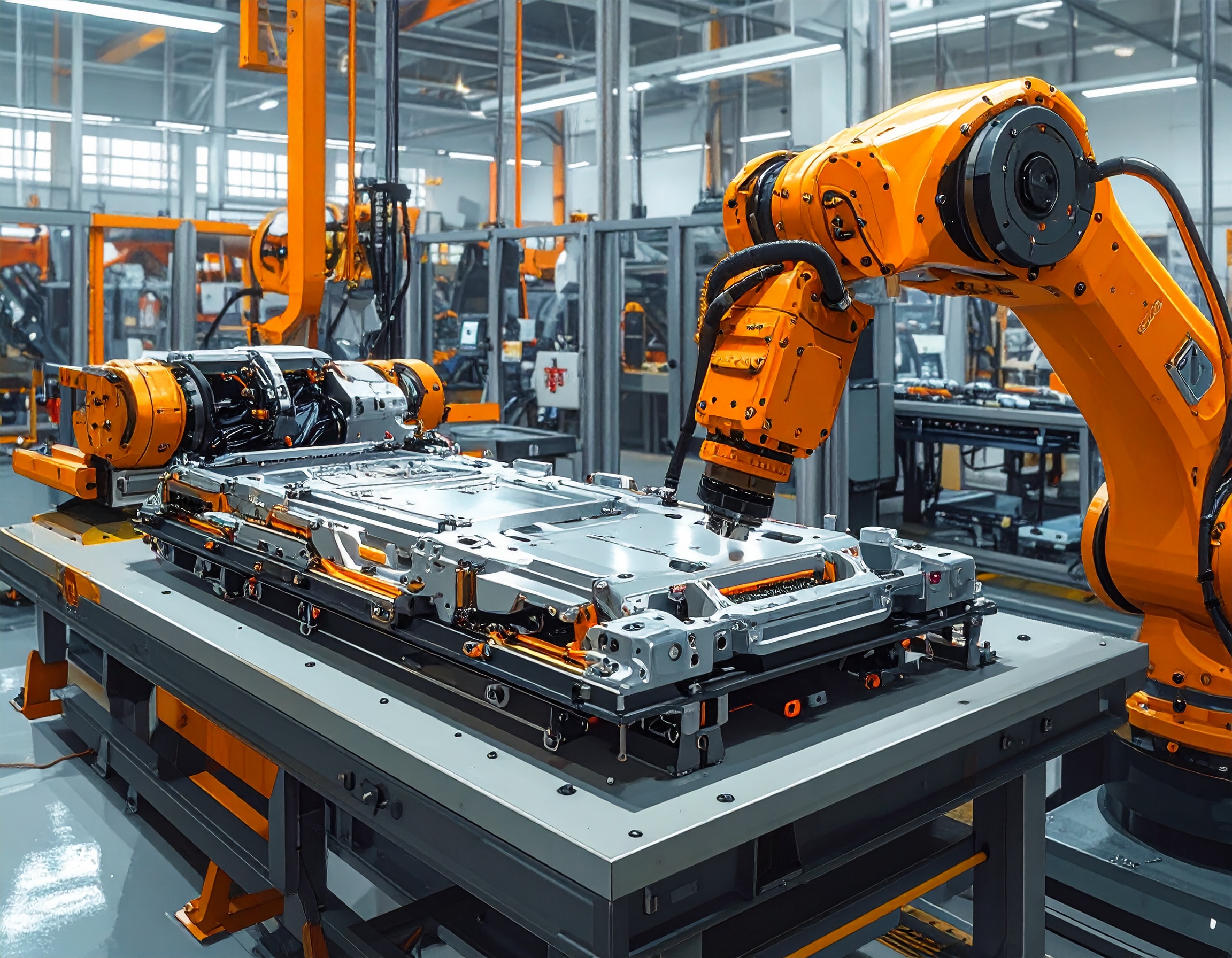

Electromechanical assemblies play an essential role in today’s industrial products. From medical diagnostic equipment to commercial automation systems, these assemblies support reliable performance by combining mechanical components with electrical elements.

Read Full

Sheet metal box fabrication plays a critical role in many industries across Canada. From electronics enclosures to medical device components, the quality of the material influences strength, durability, formability, and

Read Full

Stamped metal components are at the heart of numerous industries, including automotive, aerospace, and electronics. Metal stamping services enable the production of complex designs with high accuracy. However, the long-term

Read Full

Rapid prototyping plays a crucial role in accelerating innovation and reducing time to market. Two main approaches for prototyping services dominate the industry today: subtractive rapid prototyping and additive manufacturing.

Read Full

The aerospace industry demands the highest standards of precision, durability, and innovation. At the core of this complex field lies custom sheet metal fabrication. This process is essential for producing

Read Full

Mechanical assemblies are the backbone of numerous industries, including aerospace, automotive, electronics, and medical devices. Every assembly depends on precision, durability, and repeatability. Yet efficiency is often the deciding factor

Read Full

Custom metal fabrication plays a vital role in various industries, including aerospace, automotive, electronics, and telecommunications. For businesses that depend on high-performance components, understanding the step-by-step process behind custom metal

Read Full

Modern machines run on accuracy. From aircraft to factory equipment, each part must fit and work without fault. Engineers consider design, material choice, and tight measurements at every step. At

Read Full