Design & Developed by Themeseye

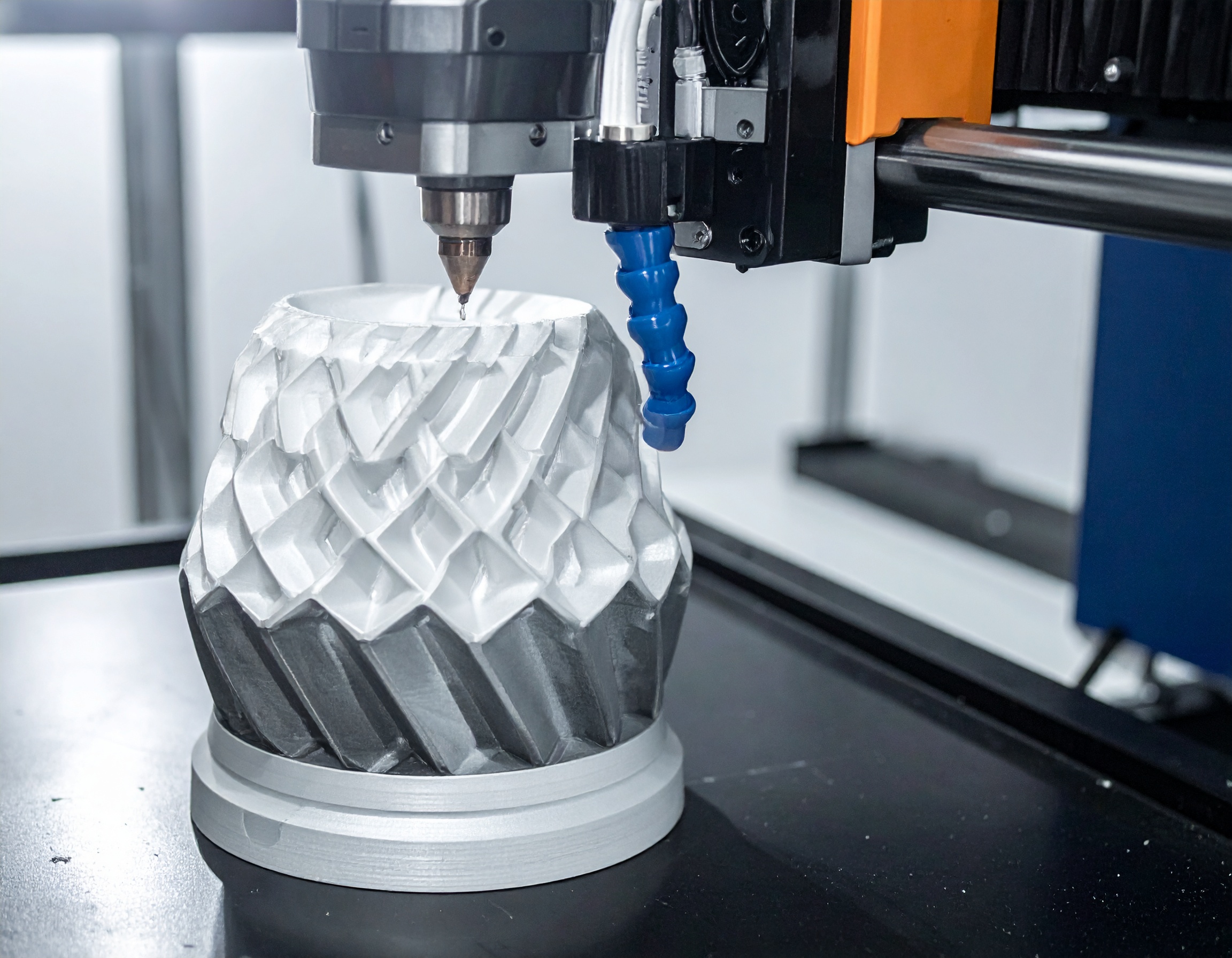

Rapid prototyping plays a crucial role in accelerating innovation and reducing time to market. Two main approaches for prototyping services dominate the industry today: subtractive rapid prototyping and additive manufacturing.

Both serve the purpose of quickly creating functional prototypes, but the technologies and applications vary significantly. Understanding what sets subtractive rapid prototyping apart from additive manufacturing methods helps businesses select the most suitable process for their manufacturing needs.

Subtractive rapid prototyping utilizes computer-controlled machines to remove material from a solid block, thereby forming a desired shape. CNC machining is the most common example, where cutting tools, drills, and mills gradually shape materials into precise components.

Key characteristics include:

This method has long been a mainstay for industries that rely on product prototyping services, where precision and durability are non-negotiable.

Additive manufacturing, also known as 3D printing, builds parts layer by layer from digital models. Instead of removing material, it deposits plastics, resins, or powdered metals until the prototype is complete.

Defining traits include:

Additive manufacturing has gained popularity across various industries, enabling the creation of lightweight or intricate structures.

While both methods support innovation, the differences between subtractive and additive product prototyping services make each better suited to specific applications.

4. Accuracy and Tolerances

Why Subtractive Prototyping Remains Essential for Manufacturing

Despite the rise of additive manufacturing, subtractive prototyping holds distinct advantages. Businesses that rely on metal components, electromechanical assemblies, or prototypes requiring mechanical strength often prefer subtractive methods. The ability to use certified materials, replicate end-use conditions, and guarantee consistency ensures that these prototypes provide reliable insights during testing.

Another advantage is scalability. Prototypes made through subtractive machining often transition seamlessly into complete production runs. This is especially true in industries where tooling and dies are already central to manufacturing.

Also Read:

Enabling Medical Breakthroughs with Advanced Prototyping

Why Custom Prototype Manufacturing is Essential for Cutting-Edge Innovation

How Custom Prototyping Shapes the Future of Product Development

Both subtractive rapid prototyping and additive manufacturing have valuable places in modern product development. Subtractive prototyping delivers precise, durable, and production-grade prototypes for metal components, ensuring consistency in testing and production transfer. Subtractive methods are well-suited for businesses that require reliable prototypes that closely resemble final products.

Promark Tool and Manufacturing offers custom prototyping services, utilizing CNC machining and custom metal stamping. The company supports Canadian manufacturers with prototypes that reflect production-ready quality and reliable performance. Contact the team today!