Design & Developed by Themeseye

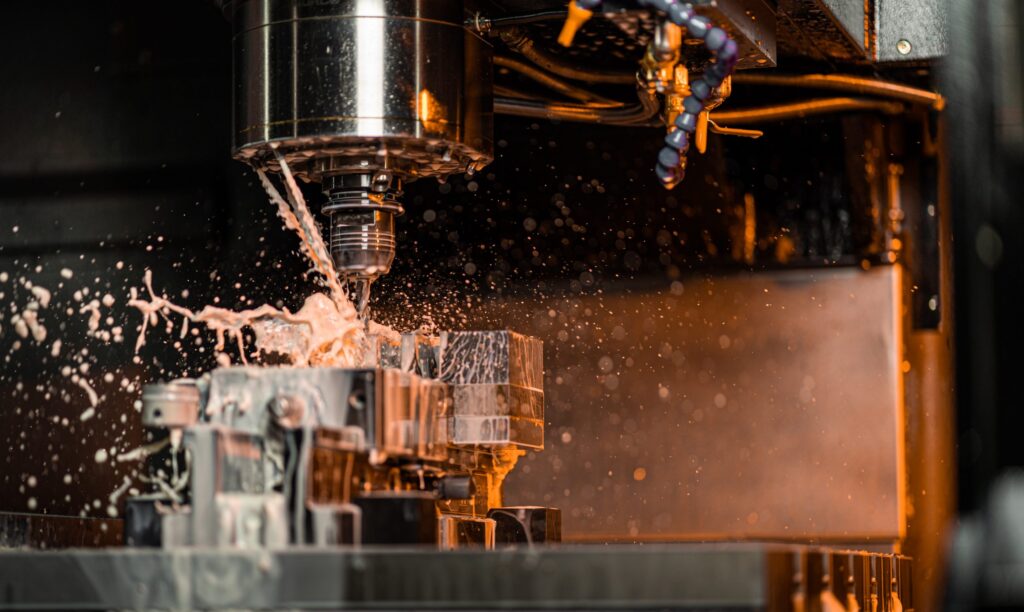

CNC machining dates back to the 1940s. While it was important at that time, thanks to improved technology, it now plays an even more critical role in manufacturing and production. To support increasing demand, this service will experience rapid growth in the coming years. Both standard and custom CNC machining help multiple industries excel, including automotive, construction, and medical.

In particular, the medical sector relies on CNC machining services more than ever. Considering all the advanced components used in this industry, it’s not surprising. In this case, manufacturers and fabricators must achieve 100 percent accuracy for every device, sensor, tool, implant, and piece of equipment produced.

Specific to the medical field, CNC metal machining isn’t just a convenient service, it’s essential. All of the things that doctors, therapists, nurses, and other healthcare professionals use to treat patients and save lives demand precision. That, along with clean machined parts and components, is what CNC machining offers to medical industry.

Most of the things used in hospitals, clinics, and doctor’s offices come into direct contact with patients. For that reason, there’s no room for error when having parts fabricated. To provide a high standard of care, everything must be consistent and precise.

Take an MRI machine as a prime example. For this large and complex system to operate safely and effectively, the custom CNC machining process is what fabricators use to produce a vast majority of the more than 100 parts and components.

However, the medical industry relies on CNC machining services for key elements beyond an MRI machine. Just a few examples of what fabricators use this technique for include:

1. Alignment screws for a CT scanner.

2. Impellers for devices that monitor the flow of fluid.

3. Gear plates for laser eye keratome.

4. Micro-tips used as instrument caps.

Not only is CNC metal machining diverse and accurate, but it’s also cost-effective. Within the past several years, the cost of medical diagnostic testing and treatment has skyrocketed. A reputable fabricator can decrease the long-term costs by making superior quality parts that will last longer.

At the same time, there’s no compromise on the quality of critical equipment and devices such as an MRI system. That means patients can go through testing and treatments safely and effectively. It all comes down to ensuring the medical sector has what it needs to provide every patient with excellent care.

While CNC metal machining is the most requested service, top fabrication companies can use a variety of materials specific to the medical industry. Fabricators can also produce small to large quantities of parts and components, as well as those with simple to intricate designs.

When it comes to having parts and components made for medical equipment, it’s important to work with a top-rated fabrication company. The combination of cutting-edge machines and highly skilled experts guarantees precision. For superior CNC machining services, Promark Tool and Manufacturing. is a trusted source.