Design & Developed by Themeseye

In search of expert tool and die design services to enhance your manufacturing processes? Look no further! At Promark Tool and Manufacturing, we specialize in providing top-notch tool and die design solutions for a customer’s next production run to a wide range of industries.

Tool and die design is a specialized field that plays a crucial role in the manufacturing industry. It involves the creation of precise tools, and dies used in various production processes. These tools and dies are responsible for shaping, cutting, and forming materials with exceptional accuracy, resulting in high-quality products. Tool and die design services for production runs encompass the expertise and technology required to design, develop, and fabricate these essential components.

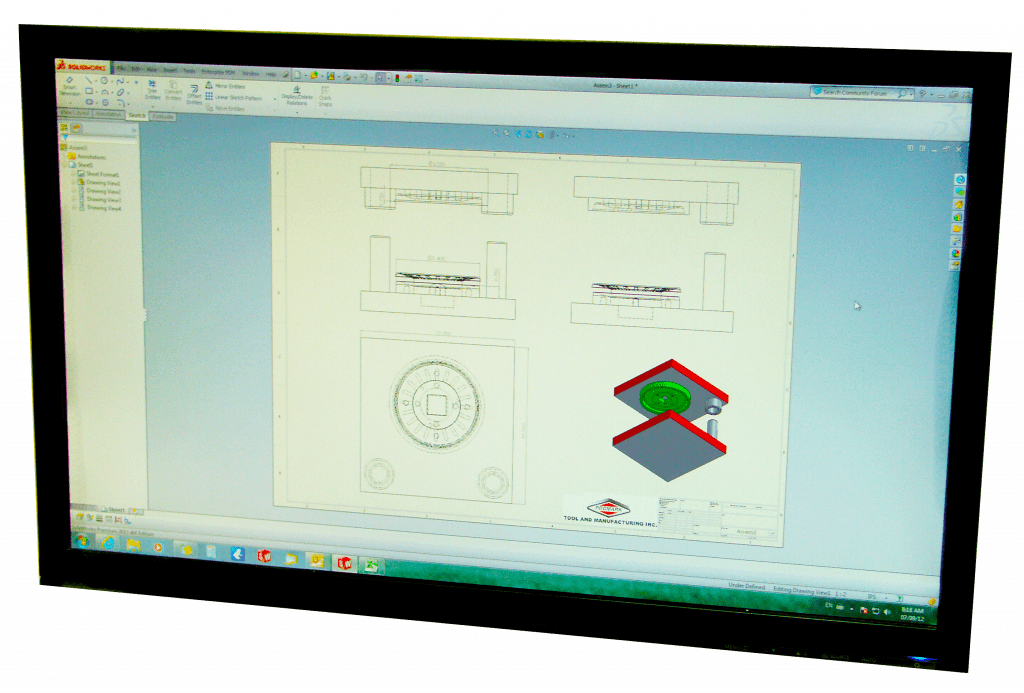

Tool and die design services employ advanced CAD/CAM software and cutting-edge manufacturing techniques to transform ideas and concepts into tangible solutions. Experienced design engineers collaborate closely with clients to understand their specific requirements, ensuring that every aspect of the tool and die design aligns with their needs for the production run. By leveraging their expertise, these professionals create precise 3D models and simulations, optimizing the design for efficiency and cost-effectiveness.

Progressive die stamping revolutionizes manufacturing by enabling efficient mass production of complex components. It involves consecutive stamping operations with a progressive die, producing multiple features in a single stroke to boost productivity and reduce production time. Our expert designers analyze product requirements, creating innovative and precise stamping die designs that guarantee durability and consistent high-quality production.

Mechanical tool and die services offer a multitude of advantages to manufacturers across various industries. Here’s why you should consider utilizing these services:

Partnering with a reputable tool and die company for design services offers numerous benefits, including:

Promark Tool and Manufacturing, a renowned tool and die company based in Toronto, Canada, has been a trusted partner in the industry since 1971. With a strong commitment to customer satisfaction and cutting-edge technology, we provide comprehensive tool and die design services for your production run with them that meet the highest standards of quality and precision.

Some of Our Clients